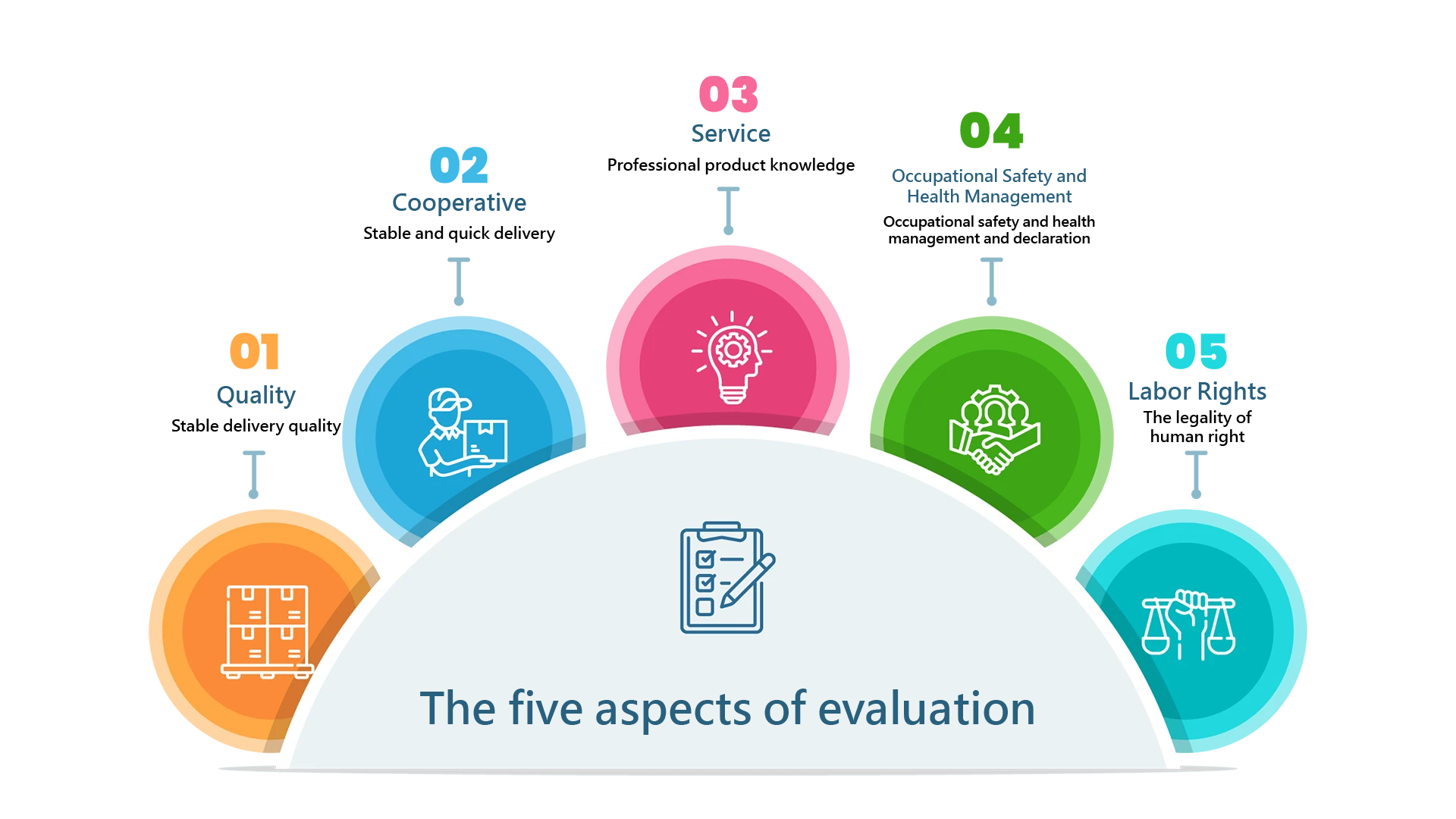

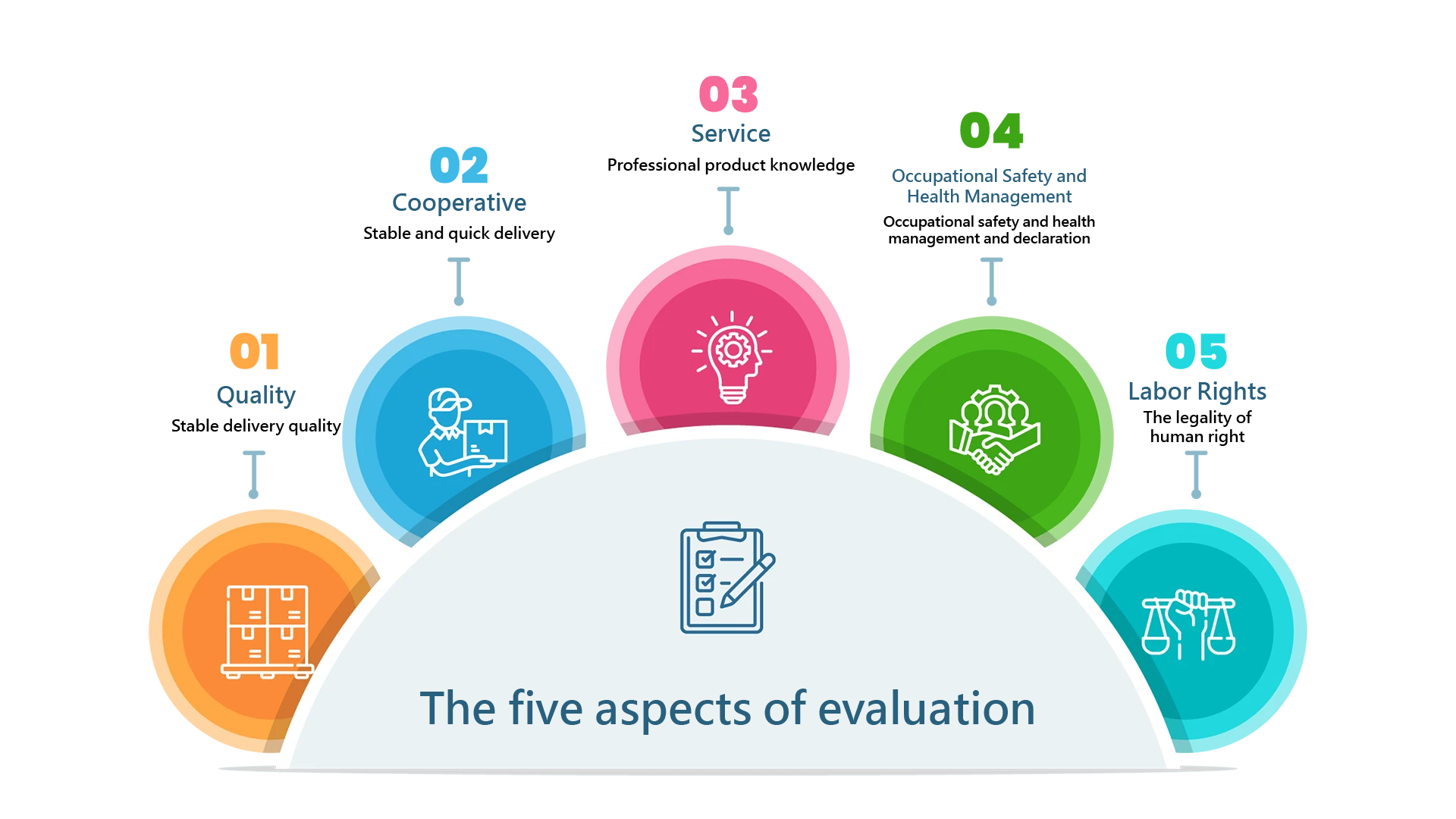

The five aspects of evaluation

Commitment and Policy

Based on the development of business activities, suppliers are THC’s important and long-term partners. By our collaboration, THC expects to be prospering with suppliers. Therefore, THC request suppliers to comply with related standards on the topics of environmental, occupational safety and health, and labor right so as to together fulfill social responsibilities.

Supplier Management Measures

Supplier Verification and Selection

Hon Chuan adheres to ISO 9001, FSSC 22000, ISO 22000, TQF, and other international standards, along with national food safety regulations. Certification is conducted by independent third-party bodies to ensure transparency, impartiality, and customer trust. Packaging and beverage suppliers with ISO 9001 or ISO 22000 certification are prioritized, and must undergo evaluation across five key dimensions to qualify,

including raw material testing.

The five aspects of evaluation

Supplier Contracts and Agreements

Both parties, THC and suppliers, agree on the rights and obligations of quality, delivery date, product inspection standards, late delivery penalties, method of loading, insurance fee, warranty liability, obligation to maintain secrecy, force majeure clauses, etc. For facility, engineering, and related contractors, THC signs contracts with them for construction period, payment terms, compliance with environmental safety regulations and construction occupational safety and health requirements, change order clause, inspection clause, delay penalties, warranties, termination clause, obligation to maintain secrecy, force majeure clauses, etc.

Supplier Evaluation

THC regularly evaluate suppliers’ performance including quality, delivery, responsiveness, occupational safety and health management, labor rights, environmental protection, etc. Each supplier is rated according to our evaluation criteria. Those suppliers rated with poor score should perform improvements; if the supplier still fails to meet the requirements, THC will terminate the procurement contract or cancel the qualification of qualified supplier.

Supplier On-site Inspection

The supplier on-site inspection is conducted by our auditors from different departments (Quality Assurance Department, Procurement Section, Occupational Safety and Health Center, etc.) to perform regular audits in accordance with the Company’s requirements. In the inspection, we measure and evaluate suppliers’ performance in specific areas, such as quality system and document control, measuring instrument management, products and process management, factory and environmental management, environmental safety and health, and human rights management, etc. In addition, suppliers of raw food materials shall submit required test reports, such as the Certificates of Origin and its registration information, upstream traceability of products and certification information, inspection report, raw material hazard analysis form, food additive license, etc. We also conduct on-site inspection of food raw material suppliers and risk assessment of food safety factors. If the evaluation result is inferior to the requirements, THC will terminate the procurement contract or cancel the qualification of qualified supplier.

Evaluation Results for the Last Three Years

In 2023, the Beverage Business Unit conducted on-site evaluations for 57 out of 119 suppliers, and the Packaging Business Unit evaluated 26 out of 178 suppliers. All evaluated suppliers received grades of Excellent or Grade A, with no suppliers rated as Not Qualified or requiring observation.

Number and Proportion of On-site Evaluations

(Evaluated Suppliers / Total Suppliers)

| 2022 | 2023 | 2024 | |

|---|---|---|---|

| Number of Evaluated Suppliers | 85 | 83 | 77 |

| Total Number of Suppliers | 296 | 297 | 333 |

| Proportion | 29% | 28% | 23% |

Suppliers Consultation

THC classifies suppliers in accordance with type and risk level; in the annual audit process, THC will counsel suppliers to improve their capability according to the classification, so as to conform to the Company’s requirements.

Suppliers Analysis

Beverage Division

Packaging Division

Supplier Risk Management

As the world moves toward net-zero emissions and green transformation, customers place increasing

importance on renewable energy and circular materials within their supply chains.

Hon Chuan ensures raw material quality and regulatory compliance through supplier validation, audits, and evaluation mechanisms. In 2024, Hon Chuan invited a total of 90 suppliers to sign the Supplier Sustainability Commitment, which covers four major areas: corporate governance, labor rights, health and safety, and environmental protection. Environmental regulations and labor rights are also included in the evaluation of new suppliers.

Supplier Integrity

All suppliers need to sign the Declaration of Integrity and the Supplier Sustainability Commitment to prohibit any unethical acts, such as accepting improper benefits in whatever form, corruption, blackmail, misappropriation of public funds (including anti-corruption).

Legal Compliance

Personnel Security

Predicting Danger

Reinforce Educational Training

Manage Cooperative Operation

Photos