Policy

To track waste flow, ensure that all waste is treated properly, and promote waste recycling

Goal

Short-term: Continues to promote waste reuse and good waste treatment in entire plants.

Mid and Long-Term: The entire plant's waste recycling rate up to 100%.

Management

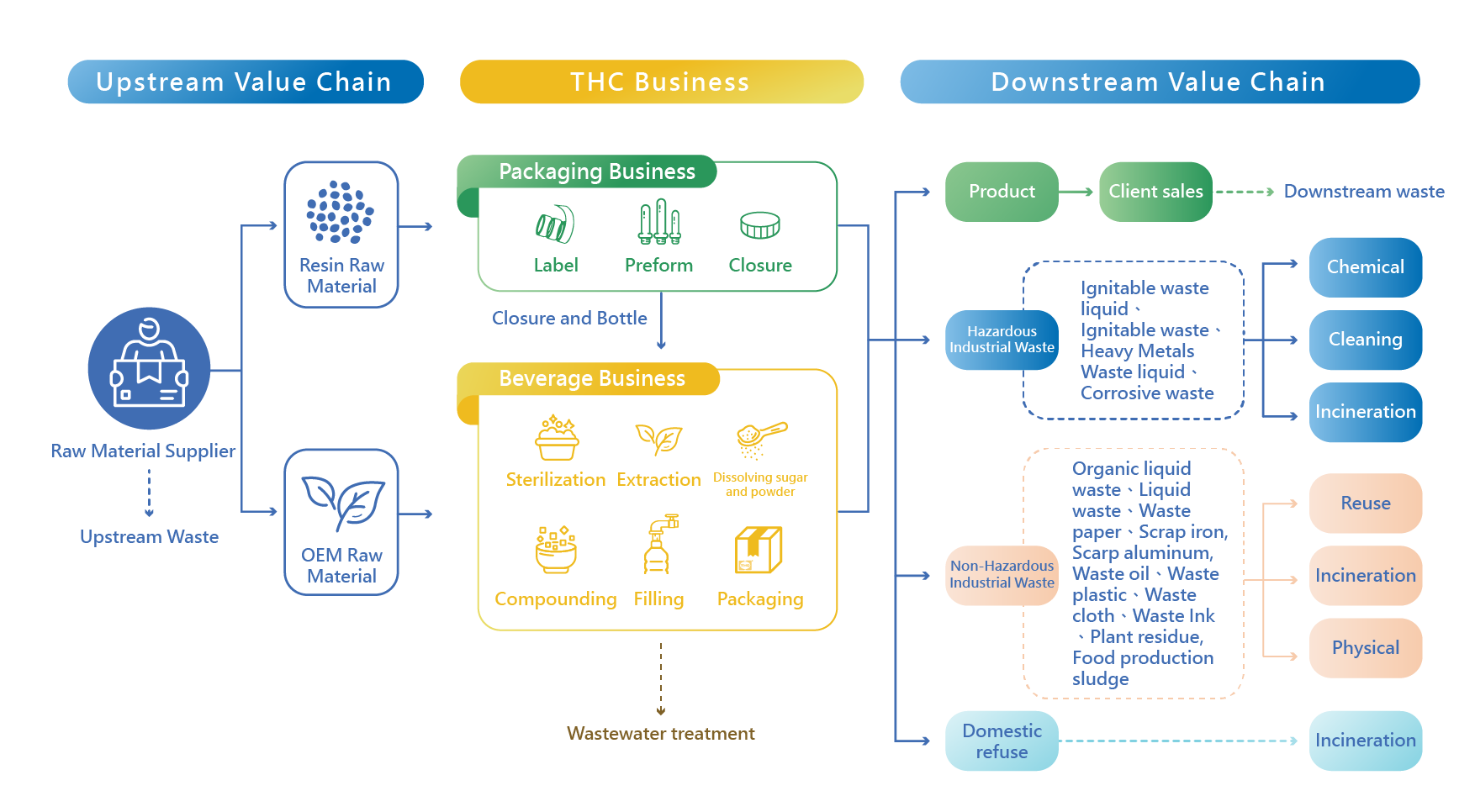

- Carry out the waste supplier evaluation mechanism and contract management, and confirm each removal and proper disposal flow.

- Increase the diversity of chemical removal channels to achieve material recycling benefits.

- Promote and implement recycling to employees and waste management control.

Conditions for waste

- In 2024, the total waste volume was 17,012 tons, an increase of 10.9% compared to 2023 (up by 1,667.4 tons). This included 16,959.7 tons of general industrial waste and 52.3 tons of hazardous industrial waste. The total waste removal volume was 17,050.87 tons, an increase of 1,691.62 tons from the previous year. Due to the phase-out of gravure printing, hazardous waste decreased by 90.7 tons, contributing to a total reduction of 46.86 tons. The company-wide waste reuse rate remained at 98%.

- Packaging Division: Plastic waste (e.g., PET preforms, caps, waste labels) is sorted and mostly reused. Hazardous waste is primarily printing ink solvents (C-0301) and their mixtures (C-0399), generally disposed of through incineration.

- Beverage Division: Main waste includes plant residues (R-0120) and food processing sludge (R-0902). Plant residues are converted into organic fertilizer, while sludge is used for biogas power generation or as boiler fuel.

Waste Volume (Tons)

Packaging Division-

Waste Emission Intensity and Recovery Rate

Beverage Division-

Waste Index