THC has taken several steps in the past three years to reduce the impact of production on the environment. This includes the implementation of a negative pressure production area, the addition of a Regenerative Thermal Oxidizer(RTO) to reduce VOCs, and an imported 10-color flexographic printing machine with environmental protection Type UV ink. This has helped to reduce the use of solvents in gravure printing and the generation of VOCs.

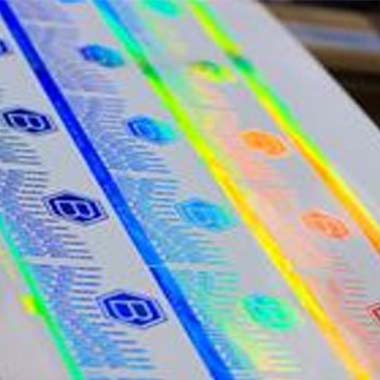

Besides improving the Flexographic Printing Machine's delicate printing, it has extraordinary applications, such as hot stamping, anti-counterfeiting printing (delicate fonts/ invisible ink), and soft touch printing. Meanwhile, it is also friendly to the

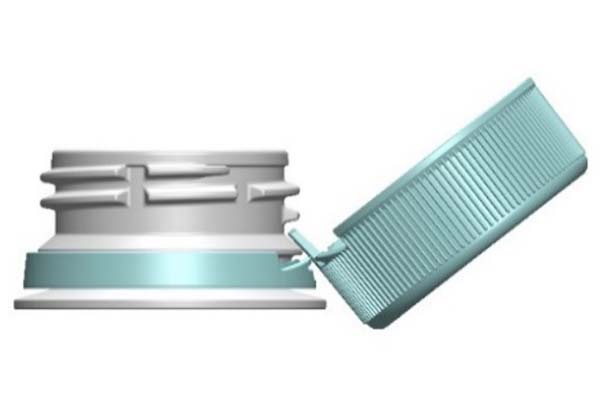

In response to the trend of beverage packaging materials in various countries and to reduce the operation of plastic recycling systems, THC innovatively designed the concept of bottle caps that do not fall to the ground and launched aseptic, hot-fulfilling, and CSD beverages for different bottle sizes and beverage production processes. Provide relevant supporting measures for customers.

Application:All products

Material cost:-

GHG emissions:2.15kg

(CO2e/kg)

Application:Water, CSD, hot fulfilling

Material cost:Higher than vPET

GHG emissions:0.45kg

(CO2e/kg)

We exported in 2024

rPET preforms

Reduce greenhouse gas emissions by about

We exported in 2024

rPET labels

Reduce GHG emissions by about

THC successfully developed rPET packaging materials

We predict that in the next 3 to 5 years, rHDPE recycled plastics will be added to the production of plastic closure. Therefore, after continuing to develop 30% rHDPE recycled plastics into plastic closure with upstream petrochemical plants, and according to the new raw material certification test method of international top manufacturers, it has passed the functional test of THC internal laboratory. In the future, if Taiwan's government approves the application and manufacture of rHDPE plastic caps, it will be able to provide customers with innovative products and reduce carbon emissions at the same time. Fulfill environmental sustainability responsibilities and create a win-win situation for enterprises, consumers, and a sustainable environment!